Share

Pin

Tweet

Send

Share

Send

I'll try to remove the magnet from the speaker. A speaker with a diameter of 350 mm, released in 1980 in Novosibirsk. The magnet should be powerful enough.

I need magnets to place a small tool on it. The magnet is attached to the wall and the tool will always be in sight.

I advise you only to place the magnets away from the vice and other places where a lot of metal dust and chips are generated when working with the grinder. Dust will be attracted to magnets.

I once heard that a magnet can be detached from the base - a metal plate - by heating. Heating the surface softens the glue and releases the magnet. If you try to knock out a magnet, then its parts may remain on the plate. Therefore, this method is undesirable.

Remove the magnet from the dynamic head

I turn off the fasteners and remove the aluminum cover.

At the bottom of the structure there is a copper disc. It can be seen that they tried to unscrew the magnet - the edges on the bolts that hold the bottom plate were torn off.

I turn the speaker over and start to burn the surface of the upper metal plate with a burner.

Important! From heating, the magnet may lose its properties, so the temperature must be regulated.

In a circular motion of the burner I heat the surface of the plate. Periodically I touch with my hand to check the temperature. After heating, I start with a chisel and hammer to beat off a metal plate.

Care must be taken because the surface is hot. After several strokes, the plate begins to recede, the room smells of glue.

The edges of the copper disc interfere. You have to hit her several times with a hammer. Then the magnet with the upper plate leaves the installation site. The plate easily leaves and I have almost a whole magnet in my hands.

The method turned out to be quite working. The metal must be heated to 70 degrees so that it begins to burn your hand. The glue becomes soft and you can separate the metal plate. After that, warm up a little more and you can start working with a chisel.

There is no other way to remove the magnet without damaging it. The magnet will either crack or partially remain on the metal plate in the form of a flange.

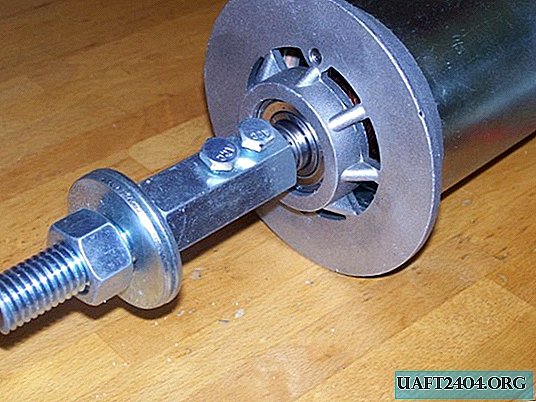

From a plate I will make a faceplate for a lathe. The plate for this must be pierced. The part is mounted to the faceplate and clamped with a bolt, and the faceplate is inserted into the turning chuck.

I used to get magnets with a diameter of 120 mm from car speakers. The diameter of this magnet is 135 mm. It is powerful to attach various tools to it, including a metal hammer. The thing in the workshop is very useful.

Tip: it is better to mount the magnet on the wall so that it does not fall from the weight of the tools.

Share

Pin

Tweet

Send

Share

Send