Share

Pin

Tweet

Send

Share

Send

How favorably the ferrocerium flint differs against the background of other means of producing fire, many articles have already been written and videos have been shot. To get a fire in extreme conditions, even in wet weather, with at least some desire, can be quite easy. There are many ways. Starting from a home-made lens from a bottle, or a light prism from the bottom of an aluminum can, and ending with the cutting of a spark, by hitting a knife with a sharp stone on the butt. Somehow, perhaps, if possible, I will describe in more detail and demonstrate a couple of such methods clearly ...

But the most reliable and faithful method remains with the use of ferrocerium flint. It gives a hot spark, with an average temperature of 1000-1300 degrees (at least, they write in the characteristics and descriptions of this thing from different manufacturers), which significantly increases the chances of making fire even for the most inept user of this product. It is impossible to make ferrocerium at home, since the above substance is an alloy of several metals. We need a laboratory, a plasma oven, the necessary knowledge in the field of chemistry, and so on ... I think that not everyone will find such equipment in the pantry. So, you want, you don’t want, but you have to buy if you need this thing. But you can always make a handle and a chair yourself. Today I want to share one more way how to make a convenient handle-holder, with a built-in chair, for the flint. That is, for a ferro-cerium rod. Especially for this purpose, I ordered several bare rods in the online store in order to independently make holders for them, taking into account my needs and amenities. It’s more likely to be discussed not even about the holder, but about the case, which will be displayed

They fit very well in size under my idea. Although, of course, on sale you can find something similar, but anyway - using a do-it-yourself thing is much more pleasant to use. The advantage of such a product is that you know that it will not crumble in your hands at the most crucial moment, as you did it yourself, and you know all its capabilities and the approximate tensile strength. So let's get started!

Will need

- Ferrocerium rod 60 × 6 millimeters.

- Two empty disposable lighters.

- A piece of high-carbon steel for a chair (it is possible from a metal sheet).

- A piece of tube, or sleeve, into which a piece of steel for a chair will fit.

Required tools and supplies:

- Soldering iron with tin and flux.

- Stationery knife.

- File or file.

- Seconds glue.

- Composite glue "Cold welding".

- Boron machine with a cutting disc (or a good, heavy knife).

- Machine oil (or weapons).

- Sprayer with water.

- Scissors.

Making flint

The first step is to release the remaining gas from the lighter. To do this, it is enough to dig a small hole in the lighter body with a sharp knife.

It’s best in a place that will be later removed or closed with something. If the lighter is empty and no longer functioning, this can be done right on the spot, without going into a draft - such a low concentration of gas (if there is one at all!) Will in no way affect either health or safety. Further, using the burr of the machine and the cutting disc, it is necessary to separate the bottoms of the lighters.

Of course, it was possible to saw off the tops, and leave the bottoms as the natural endings of the holders, but I already had one lighter with the bottom torn off earlier, so I had to improvise. So, we saw off the bottoms, and align the cut off places with a file so that they become as equal as possible.

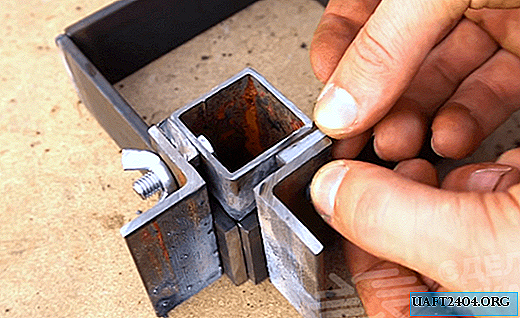

Further, with the help of a clerical knife and pliers, we tear out all of the upper parts with roots. Also, align with a file. For now, you can put the finished holders aside and start making chairs. To do this, take a piece of steel that can easily fit into any of the two compartments inside the holder body, insert it into the tube, and solder it to the tube. If the tube is too small, then weave it until a strip of steel fits inside.

We make the same extension from the tube for the ferrocerium rod.

Try on to the body.

If everything fits well, and nothing needs to be filed, and corrected, we begin to breed composite glue.

After the glue is mixed, push its pieces into the holder body and insert the flint core into one of the compartments. In the second building, after the identical procedure with glue, we install a chair, also in one of the compartments.

Next, we hammer the remaining compartments in the holder’s bodies with glue and, having greased the flint and the chair with oil so that the glue does not stick to them, we stick two blanks into each other so that the flint and the chair enter the free compartment of the opposite part of the body. It turns out something like "two in one."

We give the glue to grasp properly; an hour and a half. You can then, if there are cracks or holes near the rod of the flint or chair, drop there a drop of second glue. For greater reliability! It certainly won’t happen from this. Next, we will make the end-caps, in places where the lighter mechanisms we torn out previously were located. You could leave them, but after trying on, I realized that the look of the product would be, to put it mildly, ugly. In extreme cases, these endings can simply be covered up with the remains of cold welding, but I decided to make plugs from a thick reflective fabric.

To do this, we coat the ends of the ends with second glue, apply pieces of the desired material to a suitable size, and after 5-10 seconds we cut off the edges along the perimeter of the end with scissors.

In principle, you can finish the assembly on this, but I decided to attach a holder for a ring or carabiner to the case. Everything is as simple as that - cut out a strip of tin, mm 5-7. We wrap around one of the parts of the body, bend the tail from the ends, solder it, and drill a hole for the ring.

We put on half the width of the resulting oval hoop on top of one of the parts of the body, and fix it with glue. Further, we simply put the flint as it should, into each other - the tin hoop will hold both parts more than securely!

That's all, you can go check for usability; what is no reason to go for a walk in the forest, to conduct tests in real field conditions!

In the video clip, you can clearly see the manufacturing technology of this device, as well as real tests in real conditions.

Share

Pin

Tweet

Send

Share

Send