In this review, the author shows the manufacturing process of the spotter - this is a type of spot welding machine. Useful for repairing body parts.

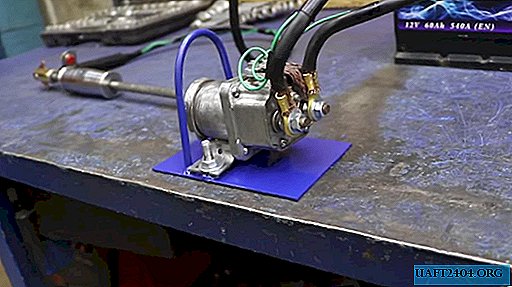

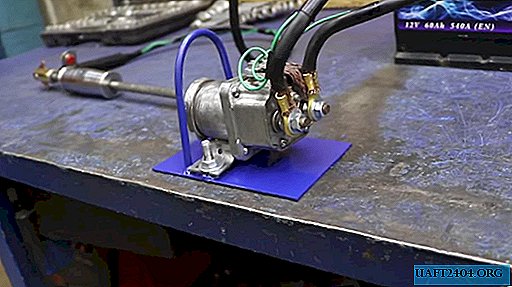

One of the main elements of this design is the vehicle starter retractor.

If you are also interested in how to make a budget option for spot welding from a microwave transformer, then detailed information can be found in this review.

First, the author parses the starter to get to the solenoid relay.

It must be checked for operability by removing the return spring of the anchor, and then disassemble and clean from plaque.

The main stages of work

At the next stage of work, you will need to cut a piece of pipe with a diameter of ½ inch, and weld an “eye” to it. A hole must be drilled nearby.

On a lathe, it will be necessary to grind a reverse hammer, a brass washer (with a thread inside), and an adapter from a hexagonal bar will also be required.

Next, you need a stock - cut it to the desired length. We put a reverse hammer, a spring on the rod and wind the adapter.

After that, it will be necessary to cut three pieces of copper cable in length: 60 cm, 100 cm and 120 cm. We clamp the veins of the copper cable into brass terminals.

From a piece of a metal plate, two bolts and a steel bar with a diameter of 6 mm, the author makes the basis for the relay. An on / off button is attached to the handle.

At the last stage of work, you will need a bolt with a pointed end, which is screwed into the washer. Then we proceed to the assembly of the apparatus.

The detailed manufacturing process of the spotter from the retractor relay of the car starter can be seen in the video on our website.