Grinding tips for the drill can be ordered on the website of Aliexpress. However, why pay money (albeit a little) and wait until the parcel is delivered, when they can be made with their own hands?

First of all, you need a steel bar (you can also take, for example, a wooden round stick) of the same diameter as the diameter of the rubber shaft of the holder.

You will also need a piece of plastic film (for example, from a garbage bag) and some sewing oil.

The metal tube is greased with oil, and then wrapped in a plastic film (instead of a piece of garbage bag, you can also use cling film). Well, then masking tape is wound on top.

The main stages of work

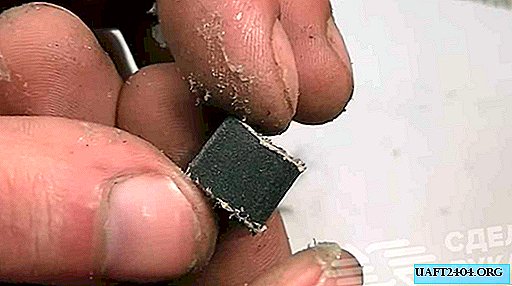

On top of the masking tape, the author wraps a layer of fiberglass mesh, which is used to strengthen the joints on drywall (when installing partitions or decorating walls). The ends are fixed with superglue.

Further, the author applies rubber glue to the fiberglass mesh (any one will do, you can even use epoxy glue for this). Next, a strip of sandpaper of the required grain size of 15 mm wide is cut.

It is best, of course, to use sandpaper on a fabric basis, but if one is not available, then it is quite possible to do on a paper basis.

A layer of glue is applied on the reverse side of the strip, and it is also necessary to smear the fiberglass mesh on the steel bar with glue a second time. Next, sandpaper is wound and left until the glue dries.

For details on how to make grinding nozzles for a drill with your own hands, we recommend that you look in the video on the site.