For the manufacture of this homemade product, a profile pipe with a cross section of 15 * 15 mm, as well as a strip of metal, will be required. The stand itself is attached to the edge of the table, and is height-adjustable, which is very convenient.

And first of all, a piece of the profile pipe that is suitable for the length must be welded to the metal strip perpendicularly (at an angle of 90 degrees).

Then the master cuts a short piece of the profile, and drills a hole in it, into which he inserts a bolt with a nut screwed on it. The nut needs to be welded.

The main stages of work

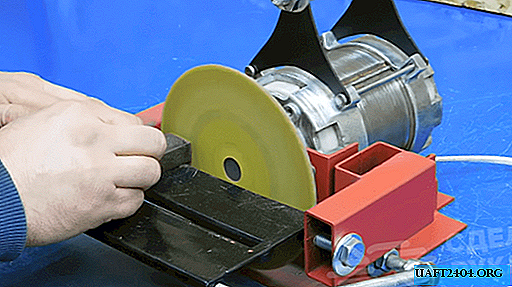

After welding, it will be necessary to clean the weld with a grinder with a petal circle. Then the master cuts off a narrow strip of metal and drills holes in it on a drilling machine (but it is also possible using an electric drill).

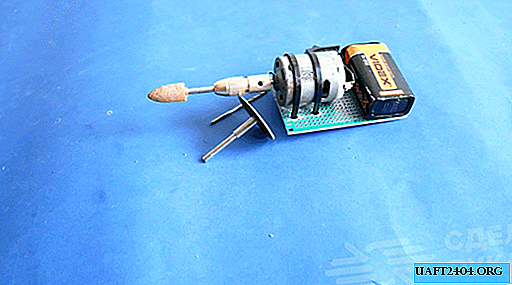

One end of the strip is welded to a short section of the profile with a welded nut, and the other is screwed to the "clothespin" of the welding mass. Then you need to weld a piece of the bar to the bolt, and you can proceed with the assembly of the structure.

The stand is attached to the table using a manual clamp. For details on how to make a height-adjustable stand for the welding mass, see the video on the site.

Write in the comments what you think about this homemade product. Constructive criticism is welcome in this case.