From the gearbox of an old mechanical drill, you can make a nozzle for an electric drill. The author is sure that with the help of such a device it will be convenient to unscrew and tighten the bolts with nuts in hard-to-reach places.

The first step is to disassemble the drill and remove the handle that rotates the main gear. Then the master cuts off a piece of the steel square and welds it to the gear at a right angle.

The main stages of work

The large gear needs to be set back to its "seat" place after removing the cartridge and cutting off all unnecessary grinder. The gear shaft will need to be lubricated so that everything spins “like clockwork”.

After everything is lubricated and assembled, it is necessary to grind the “shank" of the mechanical drill to insert it into the electric drill chuck.

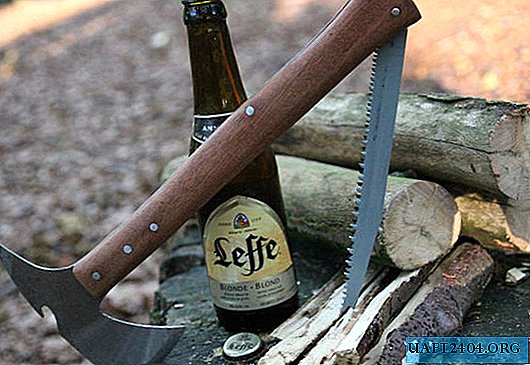

The result is a universal homemade nozzle for the socket heads, with which you can unscrew and tighten the bolts or nuts. This homemade product was conceived for use in hard-to-reach places where it is not very convenient to crawl with an ordinary electric drill.

For example, this adapt can be used to loosen the nuts under the table or in other "problem" places. For details on how to make a homemade nozzle for an electric drill from an old mechanical drill, see the video on our website.