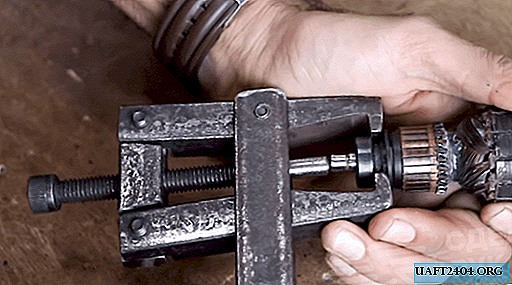

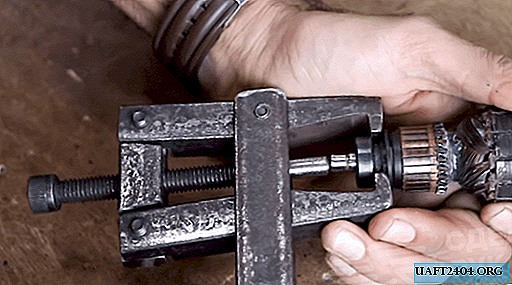

Today, there are different options for pullers that are used to remove bearings from the shaft. In this review, we will consider the simplest option, for the production of which a welding machine is not needed. The removable device will be universal and convenient to use.

To make a simple do-it-yourself bearing puller, you will need bars from a steel square, a metal plate, long and short fastening screws, a tapping tap, as well as a marker, metal file, grinder, vise, hammer.

First of all, it is necessary to prepare three pieces of a bar from a steel square, two of them are the same in length and one is about half as much. Mark the ends with a marker and cut out the corners so that then the bars are carefully inserted into each other. We clean the cut places with a file for metal.

The main stages of work

From one edge of two long bars we make cutouts, also having previously marked with a marker. We remove the burrs and smooth out the sharp corners. The next task is to connect the structure with bolts. To do this, combine the bars and drill holes: two at the edges, one in the center of the short beam from the side.

Immediately cut the threads in the holes. We connect the bars with screws, and screw a long screw into the third hole. Cut off the metal strip of the desired size, marking and slightly incising the bend, bend it with the elongated letter "P", using a hammer and a vise.

To attach the U-shaped strip with the help of bolts, we make holes with a thread in it and a long bar. We also drill it in the middle of the "crossbar". On the other long bar you need to make a recess from the outer edge in the center.

Sharpen the edge of the screw. We assemble the product using screws. Everything is ready, the work is done! Now we check: we clamp the sleeve, fix the puller with the side screw, place the pointed edge of the second screw on the bearing axis and twist. A few seconds and the bearing is removed! Such a puller is useful on the farm to any master.