Profilegib is a device for bending pipes, beams, channels. It allows you to bend metal at a given angle without heating. There are three types of such devices: electric roll forming, hydraulic and manual.

This is a universal tool that allows you to make a complex structure from a regular profile in a short time. The scope of their application is quite wide: construction, marine and automotive industry, energy and much more.

Manual profile bending machine can be used for household needs, such as: the manufacture of drains, greenhouses, water supply to the house, the arrangement of the heating system. Making it yourself is easy.

Necessary materials and milestones

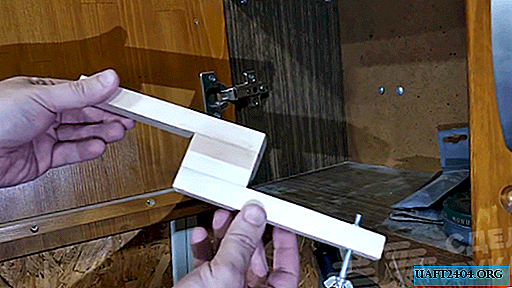

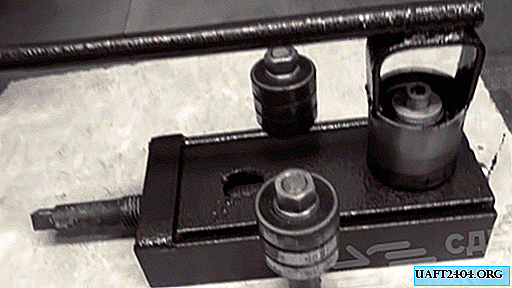

What is needed for this? Two channels of 80 and 100 mm so that one enters the other, shafts, bearings and a screw with a nut.

First of all, you need to bore the shaft under the central movable bearing, the inner diameter of which is 25 mm, and the outer - 52 mm. After grooving, it is necessary to cut the threads and weld them to the channel from two sides.

The central movable shaft is installed in the hole drilled in the channel of a smaller size. Three bearings will be put on it, which are fixed at both ends by washers and clamped by a bolt with a diameter of 10 mm. Then the bearings are pressed with a vise into a piece of pipe with an inner diameter of 51 mm.

The moving part is made of a steel blank under which the shaft is machined. The nut is welded to the inside of the channel of a larger size, and the blank itself to the upper profile. The shaft in the blank is attached with a lock nut. The moving parts must be lubricated before assembly.

It remains to weld the handle and plate so that the end of the channel does not rise with effort. If everything is done correctly, then the design will easily move by hand.

The result was a rather powerful tool that can be used for a profile 30 mm wide. This device has many advantages: first of all, it is mobility, compactness and light weight, which allows you to perform work on the spot.

If desired, and the availability of free time, everyone will do it, and improvised materials can be used as components. The entire process is shown in more detail in the video.