It is undesirable to cut boards, whetstones, chipboard sheets, as well as other blanks on a circular saw blade with blunt cutters. In this case, the performance decreases markedly. At the same time, it takes more time to sharpen the teeth of a "killed" disk than if to sharpen a disk with normal wear.

Therefore, excessive blunting of the saw should not be allowed. Need to sharpen the disk on time. And for this, a simple homemade device for sharpening carbide saw blades is useful. By the way, one of the signs that it is time to grind the disc is the appearance of traces of soot on the workpieces and the corresponding smell.

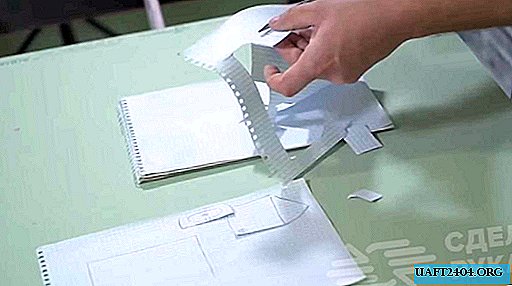

For the manufacture of fixtures, you can use one of the most budgetary materials - plywood. First you need to print paper templates on the printer, which are glued to cut-to-size boards. After that we cut out the necessary blanks.

The main stages of work

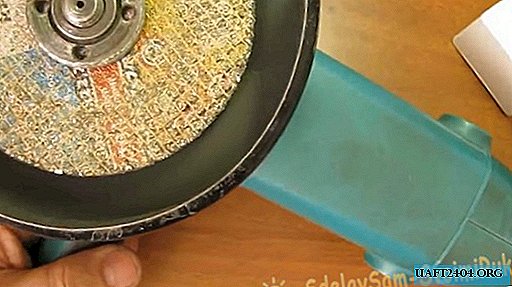

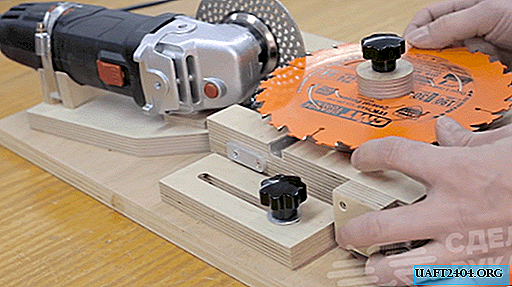

On the basis of the platform for sharpening carbide saw blades, it is necessary to use a hand milling cutter to select a semicircular groove (more precisely, a quarter circle - in the form of a half radius) along which an angle grinder will move.

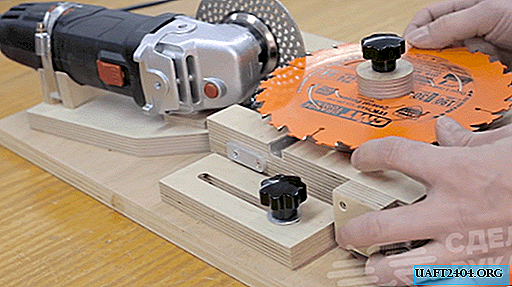

Then a bar is cut out on which the grinder will be fixed. Next, you will need to cut and fix on the base the platform for fixing the saw blade. It should move on the guides back and forth for more accurate positioning.

The base is attached to the table or workbench with clamps. See the video on our website for the step-by-step process of manufacturing a homemade tool for sharpening carbide saw blades.