Many masters, most likely, have encountered a situation at least once in their practice when, in order to fix a drill in a cam drill of an electric drill, it takes a lot of effort. Sometimes even until the knuckles turn white.

The reason for this "hemorrhoids" is the inconvenient shape and small key lever. However, this flaw can be very easily fixed. A slight refinement of the native key for the cam drill of an electric drill will help to solve this problem.

For modernization, you will need an old handle for the grinder (or you can make the handle yourself from improvised materials), as well as a wing nut. Only an angle grinder with a cutting wheel and a welding machine are required from the tool.

The main stages of work

The first step is to cut the key for the cam drill of the electric drill to the desired size. To do this, clamp it in a vice or fix it with a clamp, after which we mark the borders along the width of the wing nut and cut off all the excess with a grinder.

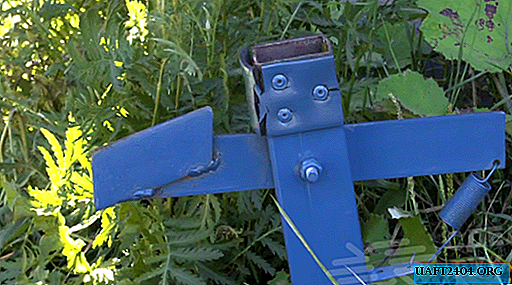

In the next step, it will be necessary to weld the wing nut to the key. Then we clean the weld with the help of a flap grinding disc for angle grinders. As a result, we get an updated key. In the wing nut, screw the handle from the grinder.

It will be much more convenient and easier to work with such a key than with a factory one. The process of finalizing the key for the cam cartridge electric drill, see the video on the site.