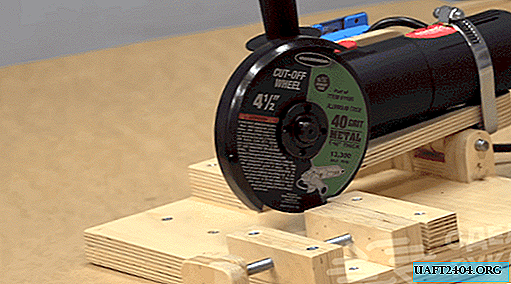

If it is not possible to buy a detachable machine for your home workshop, you can make it yourself - from pieces of plywood and a small angle grinder.

The main advantage of this design is that it can be made with your own hands from available materials (getting plywood will not be a problem), and a small grinder is inexpensive.

Using this homemade cutting machine, it is convenient to cut small parts for various crafts. Of the other advantages, it is worth noting the very compact size - such a wooden machine will not take up much space on the desktop.

The main stages of work

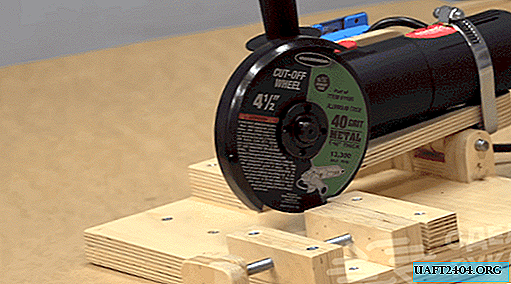

First of all, we dissolve a 20 mm plywood sheet on the blanks. The dimensions of the workpieces can be different, depending on what dimensions you need a cutting machine. Part of the workpieces will be used to assemble the base and clamp; the remaining parts will be required to make the mount for angle grinders.

We cut out small parts from plywood, drill holes of the desired diameter, and then glue them together into separate structural elements. Next, you will need to make a home-made clamp for the cutting machine in order to rigidly fix the workpieces.

At the next stage, from the previously prepared pieces of plywood, we assemble the base of the cutting machine and make fastening with a folding mechanism for the grinder. After that, we install a home-made clamp on the base and fix the angle grinder with a clamp.

Then it remains only to install a stiff spring so that after each cut the grinder returns to its original position and attach a switch.

For more information on how to make a compact cutting machine with your own hands, see the video on the website.