To make a mini circular saw, which is useful in the home workshop (for example, for sawing small parts and blanks from plastic, wood or plywood), you can do with improvised materials. You will need to buy only an electric motor and the saw blade itself.

For the manufacture of the remaining structural elements, you can use ordinary cutting boards made of plastic, a wooden block for the handle and an aluminum corner. Furniture hinges and fasteners are also required.

The main stages of work

First of all, from plastic or plywood, you need to make the lifting mechanism of the saw block of the circular saw. For this, we connect two rectangular bars to each other using furniture hinges. We attach the resulting assembly to the base, which is used as a plastic cutting board.

Then we fix the guide mechanism of the broaching mechanism from the aluminum corner. To the guide you need to fasten a small segment of the corner on which the electric motor will be mounted. We make a handle for the lifting mechanism from a wooden block and we fit it with leather.

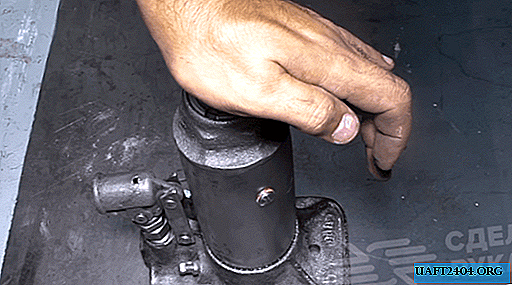

From the kitchen cutting board we cut out two halves of the protective cover for the saw blade. We insert plastic bushings (can be made of felt-tip pen or pen) between the halves of the casing and fasten them with self-tapping screws.

At the last stage, we proceed to the assembly of the entire structure and install the electric motor on the seat. We fix it with a metal clamp and a plastic screed.

For a detailed process of manufacturing and assembling a homemade circular saw for cutting plastic and wood, see this video.