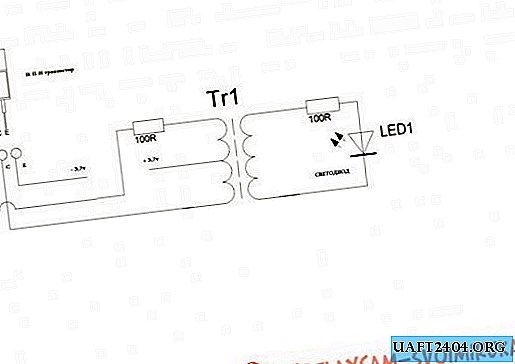

If you are tired of constantly turning the screw of the mechanical jack manually to lift the car, then it can easily be upgraded. To implement this idea, you will need a regular 12 V motor with a gearbox from the car wipers, as well as a small home-made cardan, which is necessary to transmit rotation between the shafts.

The main stages of work

First of all, you need to make a cardan, and then connect with it a motor with a gearbox and a mechanical jack. Then it will be necessary to make a stand for the jack - for this, two short segments should be welded perpendicularly along the edges of a long strip of metal.

Next, we drill holes for fastening to the body of the jack and fasten it to the studs with nuts. Then the surface can be cleaned with a grinding disc, degreased and painted with spray paint.

Thanks to such a simple drive, raising and lowering the car with a mechanical jack can be much faster and more convenient. As a power source, you can use a regular car battery. You can also make an adapter to connect to the connector on the panel in the car.

Practical application

It is very simple to work with the jack to which the motor with the gearbox is connected. We install the jack in the right place on a flat surface (if necessary, you can put a board), and then turn on the engine. The detailed manufacturing process of this home-made device and its operation can be seen in the video on the website.