In the home workshop, there is always enough work: to cut boards or bars to size, cut the metal workpieces of the required length, and process the details with a file. It is not always convenient to do this in a vice, therefore it is more advisable to use quick-clamping clamps to fix the processed materials.

Since factory models are expensive, it will be cheaper to make home-made spring-type clamps, which are compact in size and practical to use.

To make this home-made device you will need the following materials:

- profile pipe 15x15 mm;

- steel plate and strip;

- long studs with nuts;

- two springs and a file.

The main stages of work

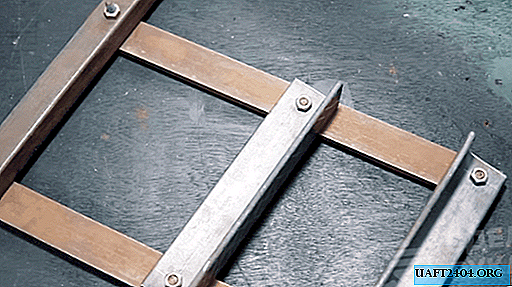

Cut a piece of the profile pipe 15x15 mm 18 cm long and weld it to the plate at an angle of 90 degrees. We weld a small segment of the file to the same plate, which will serve as a fixed clamping jaw. Further, in another plate, it is necessary to make a square hole with a drill and a drill.

The resulting part is slightly bent in a vice, after which we weld to it a piece of steel strip, in which it is necessary to drill two holes along the edges. We make markings on the surface of the file, and then we weld the studs - they need to put on a piece of steel strip.

We press on top with the previously manufactured part, after putting on the spring studs. At the last stage, we join both parts of the design of the quick-clamp clamp with each other. For a more aesthetic appearance, the surface of the tool can be painted with spray paint.