In this article, we will tell you how to make a ring bending machine (some masters call it also a bending machine) with your own hands from metal waste that can be easily found in a workshop, production workshop or garage. The device will become a loyal assistant when creating various crafts, which require wheels, metal circles or curved elements.

For a creative experiment, we need:

- several pieces of iron of rectangular cross section;

- scrap or reinforcement of large diameter;

- nine bearings (the quantity varies based on your tasks);

- electric welding machine.

The process of manufacturing a ring bending machine from trash

First of all, we grind a metal bar in a vice and saw it into three identical parts. Next, you need to grind round scrap on a lathe. One end should freely bear the bearings. At the other end of the crowbar, you need to grind a retaining cap.

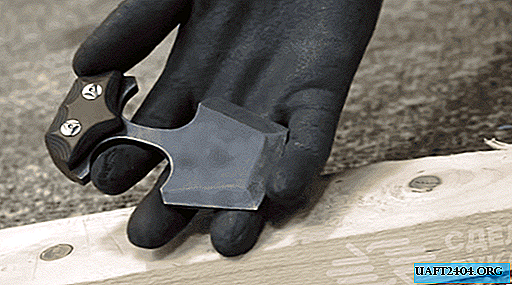

At the next stage, we drill through rectangular blocks. The resulting holes are designed for hats made earlier bolts, fasteners. We connect the parts together, we install bearings. Together with the bearings, a cylinder is put on the middle pin, to which the lever is welded.

The resulting handle rotates freely at three hundred and sixty degrees. Using welding, we fasten the base of the two parts of the machine, forming the letters "P" and "T". When clamped in a vice, the middle part moves relative to the side, fixing the workpiece. The rotation of the handle bends the product. For an aesthetic effect, the elements can be painted.

Summarize the work performed

With the help of our own adaptations made in the future, you can create other, no less useful and interesting ways. The resulting mini-machine will be an inexhaustible source for crafts. For example, it helps to artistically bend a thick wire or cut rings from a metal tire.