Using this home-made device, you can quickly fix two workpieces (for example, segments of square shaped pipes) in order to weld them to each other in a high-quality manner. This tool is definitely useful to everyone who is engaged in welding work at home or in the workshop. And to make it very simple.

Of the basic materials, you will need two pieces of steel strip, an angle of 40x40 mm, two pieces of a round bar and a bolt with a nut. To make a home-made fixture, you will need to use a grinder with a cutting and grinding discs, as well as a welding machine.

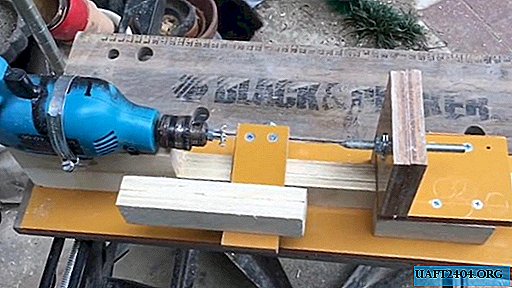

Step-by-step process

A piece of 15 cm long needs to be cut from a steel strip 30 mm wide. Then, two pieces 10 cm long should be cut from a corner of 40x40 mm - in the center of the segments it is necessary to cut a rectangular “window” grinder. Next, in the plates we drill a through hole exactly in the middle of the workpiece and connect them with a bolt and nut.

At the next stage, the surface of the steel corners is ground, and the angle on one side of the plates needs to be sharpened a little on the emery machine. Then we weld the corners along the edges of the strips, and on the opposite side - two round rods that will serve as handles.

At the last stage of work, the surface of the tool is processed with a grinding disc - in the end, a very convenient and practical manual clamp-clamp for welding profile pipes is obtained. The manufacturing process of this device can be seen in the video on the site.