Before proceeding with the manufacture of a vibrating table, you need to determine its size. In this case, you need to focus on the dimensions of the forms themselves that you plan to use.

At home, a large vibrating table is not needed, but it is also very tiny - also to nothing. Therefore, when determining the dimensions, it is necessary to take into account the performance of work that would be optimal for you.

Now for the top of the table. For this, it is best to use a sheet of metal with a thickness of at least 4 mm. And note that if the sheet is a curve, then it will need to be aligned.

The main stages of work

The first step is to cut off four pieces of the corner and weld them to a sheet of metal. But not end-to-end, but under the bottom of the sheet with an indent from the edges of 2 cm.

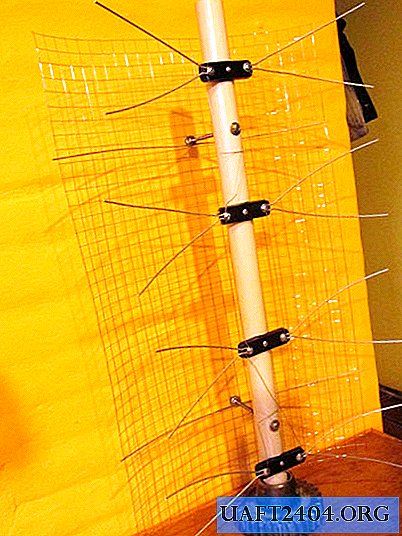

Next, from a metal strip 30-40 mm wide, it will be necessary to cut eight workpieces 6 cm long. Then they must be welded together to make two identical workpieces.

After that, we drill one hole in the workpieces, and put them on the motor shaft. It will be eccentrics. Then they will need to be scalded.

In order not to burn the motor winding, it is advisable to put the bed on a piece of wood or plywood, and the current should be sent directly to the shaft. In the process of welding itself, you need to take breaks so that the grease does not leak out of the engine.

Production of a frame for a vibrating table

To make the frame, the author uses a profile tube of square section 30x30 mm. Since the dimensions of the vibrating table in this case are small, a profile of 30x30 mm will be quite enough.

In the frame, it will be necessary to additionally drill holes for a round bar with a diameter of 12 mm, on which rubber bushings of jet rods will then be put on. They just freely put on the bar.

These rubber bushings are needed in order to separate the upper part of the vibrating table and the frame, because if they are rigidly connected to each other, then there will be no use from the vibrating table.

The author also decided to make the legs of the frame from a profile of 30x30 mm. The electric motor itself is mounted under the vibrating table (under its upper part). Then you can start assembling and painting.

In detail about how to make a vibrating table from a conventional electric motor with your own hands, we recommend that you look in the video on our website.