Sometimes you have to work with soft materials (leather, wood, etc.), the surface of which, when fixed in a vice, is easily damaged by corrugated metal sponges. But this problem can be solved very simply - just make replaceable jaws for a vice from plastic.

As the main raw material for the manufacture of sponges, you can use empty plastic bottles and cans from household chemicals.

Prepared containers must be cut into small pieces with a knife or scissors, then poured into an aluminum mold and sent to the oven, which must first be heated to 350 degrees, for 10-15 minutes. As a result, you should get a rectangular plastic block.

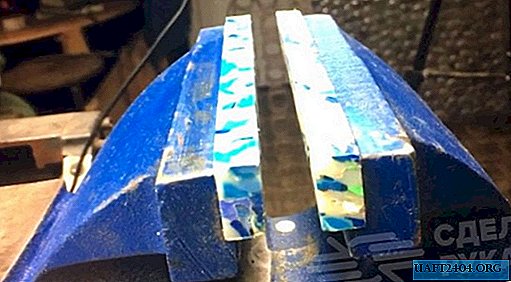

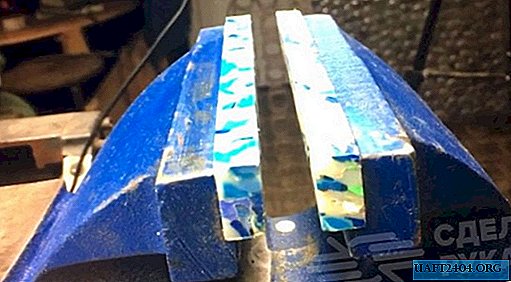

Workpiece processing

The sides of the plastic bar are evenly cut on a circular saw, and the ends of the workpiece are trimmed on a trimming machine. Then we process the main and lateral plane of the plastic bar on the jointer, after which we pass the workpiece through the thicknesser.

As a result of all these manipulations, we get a perfectly even block of plastic. Next, we remove the native metal sponges from the vice that you plan to work on, and based on their actual size, we cut the sponges out of plastic. Well, then everything is simple - we drill holes in the right places for the bolts and screw the interchangeable jaws to the vice.

After processing wood products or other soft materials, plastic sponges are easy to remove, to put your family - from metal. The main stages of the work you can see in the video on the site.