When assembling furniture for reliable and rigid connection of pieces of chipboard, eccentric screeds (or so-called minifixes) are often used.

To correctly install the eccentric couplers, first you need to accurately drill holes in two workpieces. It’s impossible to do by eye.

Therefore, beginners will come in handy a simple home-made conductor, which is designed to drill holes of a certain diameter for eccentric couplers.

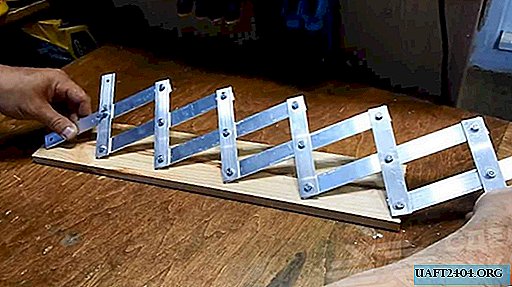

To make it, you will need a small piece of plywood or a wooden bar, plexiglass and a piece of metal tube, as well as a pair of screws.

The main stages of work

First of all, it is necessary to saw off a wooden block of 30x30 mm with a length of about 60-70 mm. On one side, the author makes the markup.

Next, in the bar, you need to drill a hole for a metal tube with a diameter of 8 mm. The length of the tube itself is 42 mm.

At the next stage, the author cuts a piece of plexiglass, and then screws it to a wooden block.

Then it remains only to make markings on a piece of plexiglass and drill four holes at different distances from each other (9.5 mm, 24 mm, 34 mm and 42 mm from the edge of the bar).

The homemade product is ready - you can try it in work. To do this, we attach the device to the workpiece and mark the place for drilling the hole.

In one workpiece we drill two holes (from different sides), in the other - one hole. Then we connect them together using the minifix.

For details on how to make a simple mini conductor for eccentric couplers, we recommend that you watch in this video.